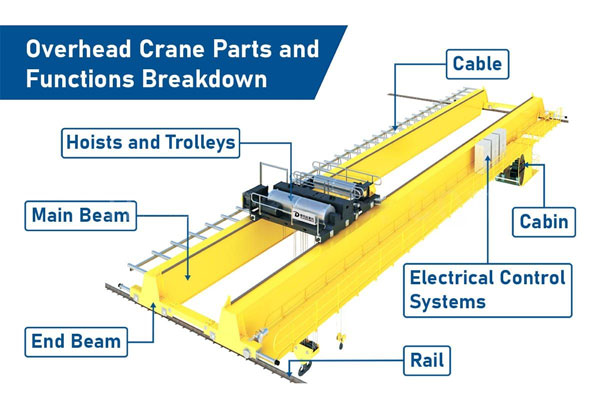

Overhead Crane Components

If you’re looking to understand the various components of an overhead crane, this guide is tailored for you. It breaks down the main parts, accessories, and assemblies of a typical overhead crane, explaining their functions and importance in daily operation, maintenance, and troubleshooting. Whether you’re an operator, maintenance technician, or new to the overhead crane industry, this article will help you grasp how each crane component contributes to the overhead crane’s overall performance and safety.

To purchase crane parts and components, click our overhead crane parts page.

Crane Frame

The frame serves as the backbone of the overhead crane, bearing the entire load and supporting all other mechanisms. It is engineered for high strength and stability to ensure safe operation under heavy loads.

Main beam

The main beam is the core load-bearing structure of the overhead crane. Typically made of high-strength steel, it features a design resistant to bending and torsion, ensuring stability even under heavy loads. Its primary functions include:

• Supporting the trolley and hook assembly.

• Providing a rail for the trolley to move smoothly along the beam, enabling precise load positioning.

The main beam’s structural integrity directly impacts the overhead crane’s maximum load capacity and operational safety, so it undergoes rigorous quality checks during crane manufacturing.

The type of main beams are single girder and double girder. So, on the basis of main beams, overhead cranes are divided into single girder overhead crane and double girder overhead crane, and you can click our overhead crane products page to see more details.

End carriage

End carriage (also known as end beam) connect the two ends of the main beam, forming the complete bridge structure and supporting the entire overhead crane. Positioned on both sides of the overhead crane, they enable the entire system to travel along the runway rails. Key features of end carriages:

• Equipped with travel drives or wheels, and connected to the overhead crane’s travel mechanism for stable movement along rails.

• Designed for high strength and durability under heavy loads, playing a critical role in the overhead crane’s overall stability and maneuverability.

Cabin control

The cabin control is the control center where the operator manages the overhead crane. It is usually suspended below the main beam or placed in a position that offers a clear view of the working area. Key design and functional aspects:

• Prioritizes visibility and safety, with large windows to monitor load movement and the surrounding environment.

• Equipped with a control console or cam controller for precise hoisting, trolley travel, and bridge travel operations.

• Designed for operator comfort: includes air conditioning, ventilation systems, and ergonomic seats to reduce fatigue during long shifts.

• Accessible via vertical or inclined ladders connected to walkways on the overhead crane structure.

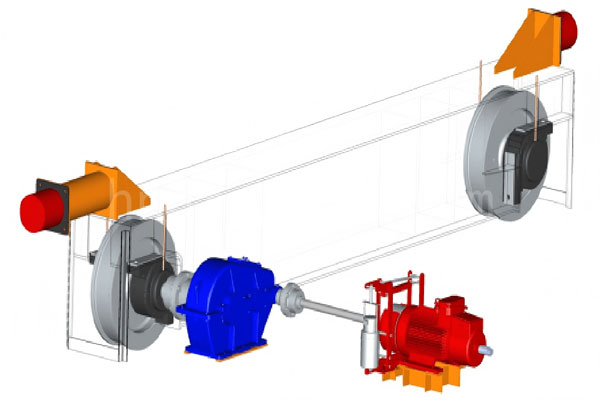

Crane Travel Mechanism

The travel mechanism enables the crane bridge (and trolley) to move horizontally along the runway rails, facilitating wide-range load coverage. It consists of five key components working in tandem.

Wheels

Crane wheels are critical to the travel mechanism, typically mounted at the bottom of the end carriages. They bear the entire weight of the overhead crane and move along the runway rails. There are two main types:

• Drive wheels: Powered to propel the overhead crane along the rails.

• Idler wheels: Assist in smooth movement, reducing friction and ensuring stability.

Made of high-strength alloy steel, these wheels are wear-resistant and impact-resistant, even under heavy loads and frequent movement. Precision machining ensures low-noise operation and extended service life, while minimizing rail wear.

Travel Motor

The travel motor converts electrical energy into mechanical motion, driving the crane bridge and trolley to move horizontally along the rails. Key characteristics:

• Works with a gearbox to reduce the motor’s high-speed rotation to a lower speed while increasing torque, providing sufficient traction for stable crane movement.

• Engineered for precise speed control, ensuring smooth starts and stops to avoid load sway.

Reducer

The reducer is a critical transmission component between the motor and wheels. Its primary role is to:

• Reduce the high-speed output of the motor to a low-speed, high-torque output, enabling stable crane travel.

• Use multi-stage gear transmission to ensure smooth movement along rails and deliver adequate pulling force.

Constructed from high-strength, wear-resistant materials, the reducer withstands frequent starts, stops, and load changes, with a long service life. Precise gear ratios ensure smooth acceleration, deceleration, and positioning.

Brake

Brakes are essential safety devices that ensure the overhead crane stops reliably on the rails. Installed on the motor’s output shaft, they act via mechanical or electromagnetic force. Key functions:

• Apply force quickly when braking is required, stopping the overhead crane accurately and preventing uncontrolled movement due to inertia.

• Designed for heavy loads and frequent start-stop cycles, with overheat protection and automatic adjustment features to maintain effectiveness over time.

Coupling

Couplings connect the motor to the gearbox (or the gearbox to the wheels). Their roles include:

• Transmitting torque and compensating for minor misalignments between connected shafts.

• Absorbing shocks and vibrations during operation, protecting transmission components and ensuring smoother power transfer.

Lifting Mechanism (Crane and Trolley)

The lifting mechanism is responsible for vertical lifting and horizontal movement of loads. Common hoisting devices include hoists and open winch trolleys:

• Single-beam overhead cranes typically use electric hoists or manual hoists.

• Double-beam overhead cranes may use electric hoists or open winch trolleys.

Hoists are mounted on trolleys that travel along the main beam, while open winch trolleys (installed between two main beams) handle heavier loads. Below are the key components of the lifting mechanism:

Pulleys

Pulleys guide the wire rope in the lifting mechanism, changing the rope’s direction and distributing the load to enhance lifting capacity. There are two main types:

• Fixed pulleys: Change the direction of the wire rope’s movement (no load reduction).

• Movable pulleys: Move with the load, reducing the force required to lift it.

Pulley rims feature grooves to secure the wire rope, preventing slippage or wear. Multiple pulleys (forming a “pulley block”) multiply the overhead crane’s load capacity while reducing the required motor power—making them critical for efficient hoisting.

Hook

The crane hook connects and carries the load, usually made of high-strength alloy steel for durability. Key features:

• Equipped with a safety latch to prevent accidental load disengagement during operation.

• Available as single hooks (for light to medium loads) or double hooks (for heavier loads, distributing weight evenly to improve stability).

• Rotates 360 degrees for flexible load handling from different angles.

Other lifting attachments (e.g., grab buckets, electromagnetic lifters) may replace the hook based on application needs.

Hoisting Motor

The hoisting motor is the power core of the lifting mechanism, designed for high torque, low speed, and precision. Key requirements:

• Delivers strong starting torque to initiate movement smoothly under load.

• Often paired with a variable frequency drive (VFD) or speed control system, allowing operators to adjust lifting speed precisely—improving positioning accuracy and operational flexibility.

Reducers

Reducers connect the hoisting motor to the drum, acting as key transmission components. Their main function is to:

• Convert the motor’s high-speed rotation into low-speed, high-torque output suitable for hoisting.

• Use multi-stage gear transmission to gradually reduce speed and increase torque, providing the necessary power for lifting heavy loads.

Brake

Brakes in the lifting mechanism control and hold the load during lifting or lowering, preventing uncontrolled load descent. Installed on the motor or reducer output shaft, they:

• Activate quickly when hoisting stops or in emergencies, keeping the load stable.

• Ensure safe operation even if power is interrupted (fail-safe design).

Drum

The crane drum is the component around which the wire rope is wound and unwound, controlling the vertical movement of the hook or other lifting attachments. Key design elements:

• Grooved surface to keep the wire rope neatly arranged, preventing slippage or overlapping (extending rope life and reducing wear).

• Sized (diameter, groove depth, pitch) based on the wire rope specification and overhead crane’s design load.

• Equipped with a rope guide to maintain orderly winding and prevent tangling.

Proper drum design and maintenance are critical for smooth hoisting and safe operation.

Wire Rope

Wire rope is the load-bearing component of the lifting mechanism, connecting the hook, pulley block, and drum. It enables lifting and lowering via winding on the drum. Key considerations:

• Diameter, tensile strength, and corrosion resistance vary by application (e.g., outdoor cranes use corrosion-resistant rope).

• Wear, broken strands, or deformation compromise safety—regular inspection and maintenance are required to ensure reliability.

Electrical and Control System

The electrical and control system is the “brain” of the overhead crane, managing power distribution and operational control. It consists of three main parts:

Busbar

The busbar is the overhead crane’s primary power supply system, typically installed on one side of the runway rails. Composed of parallel copper or aluminum conductive rails, it:

• Provides continuous power to the crane bridge and trolley, ensuring uninterrupted operation of all electrical devices.

• Includes guide rails, current collectors, and insulating supports:

◦ Current collectors (mounted on the bridge or trolley) slide along the busbar to collect electricity and transmit it to the crane’s motors and controls.

◦ Insulating supports secure the busbar and isolate it from the structure, preventing electrical leakage.

Precise alignment during installation is essential to avoid poor contact or bouncing of current collectors, which could disrupt power stability.

Power Cables

Power cables supply stable electricity to the crane’s electric hoist/winch trolley, drive system, and control system. Key features:

• Routed along the crane frame or trolley, guided by cable tracks or brackets to allow free movement with the bridge or trolley (preventing pulling or damage during operation).

• Rated for high flexibility and durability to withstand frequent bending and environmental stress.

Control Systems

Overhead cranes use three main control methods, each suited to specific operational needs:

1. Cab Control

An independent cabin control is mounted on the overhead crane (usually below the main beam or near the trolley). Operators control all the overhead crane functions (bridge travel, trolley travel, hoisting) via a console or cam controller. Advantages:

• Excellent visibility of the working area, ideal for complex, heavy-load tasks.

• Ensures high precision and safety for critical lifting operations.

2. Remote Control

Operators use a handheld remote control to manage the overhead crane via radio signals, working from a safe distance. Advantages:

• High flexibility, suitable for environments with limited visibility or potential hazards.

• Functions include start/stop, acceleration/deceleration, and hoisting/lowering—enhancing safety and convenience.

3. Pendant Control

A wired control method using a hanging control box (“pendant”) near the overhead crane or hoisting device. The pendant features buttons for basic actions (lift, lower, forward, reverse). Advantages:

• Easy to use, ideal for short-distance movement and simple operations.

• Allows operators to closely monitor the load and control the device directly, ensuring precise lifting.

Rail System

The rail system provides a stable path for the overhead crane’s movement, supporting the overhead crane and its load. It includes two key components:

Guide Rails

Guide rails are critical for smooth crane travel, typically installed on load-bearing beams on both sides of the building. Key characteristics:

• Made of high-strength steel for wear resistance and impact resistance, capable of supporting the overhead crane and its load.

• Common types include steel rails and I-beams, selected based on load capacity and environmental conditions.

• Precise calibration during installation ensures stable operation (no deviation or vibration). Regular inspections (for parallelism, wear, and fastener tightness) and maintenance (cleaning, lubrication, replacement) extend service life.

Runway Beams

Runway beams support the guide rails and crane travel, installed on building columns or independent supports. Key requirements:

• Sufficient strength and rigidity to withstand the overhead crane’s weight, load, and dynamic forces during operation.

• Made of high-strength steel or concrete, with precise calibration and fixing to keep rails level and straight (preventing instability from bending or uneven settlement).

Proper design, installation, and maintenance of runway beams are foundational to the overhead crane’s safe and reliable operation.

Safety Protection Devices

Safety devices are essential for protecting operators, preventing equipment damage, and ensuring safe crane operation. Common devices and their functions include:

• Emergency Power Off Switch: Quickly cuts off the overhead crane’s main power and control circuits in emergencies, usually located in the electrical cabinet.

• Alarm Bell: Provides an audible warning during overhead crane operation (activated via a foot switch) to alert nearby personnel.

• Overload Limiter: Installed on the lifting mechanism, it triggers an alarm when the load reaches 90% of the rated capacity and automatically cuts power if the load exceeds 105% (preventing overload damage).

• Upper Limit Protection: A limit device on the lifting mechanism that cuts power automatically when the hook reaches its upper travel limit (preventing wire rope overwinding).

• Travel Limit Switches: Installed on both sides of the bridge and trolley travel mechanisms, they cut power and allow reverse movement when the crane/trolley reaches its travel limit (preventing collisions).

• Lighting System: Provides sufficient visibility for operators and the surrounding area, ensuring safe operation in low-light environments (e.g., night shifts or indoor facilities with poor lighting).

• Buffers: Safety devices installed at the ends of the overhead crane’s metal structure, absorbing collision energy to reduce impact (protecting the crane and runway).

Summary

Every component of an overhead crane directly impacts its performance and safety—so ensuring stable, efficient operation of each part is critical. Henan Dejun Industrial Co., Ltd. as a professional overhead crane manufacturer and component supplier, we offer high-quality crane parts tailored to your needs.

Whether you require electric hoists, winches, main beams, rails, or custom components, we provide solutions designed to meet your specific operational requirements. Our team of experts ensures that all parts adhere to strict quality standards, delivering reliability and durability for long-term use.

If you have any inquiries, you can feel free to contact us to learn more about our crane products and how we can support your needs!

- The last one:Introduction to Electric Winches

- The next one:No information!

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067