Introduction to Electric Winches

An electric winch is a type of lifting equipment that uses a drum to wind up steel wire rope to lift or pull heavy objects from horizontal, vertical, or inclined directions through electric power. It occupies an important position in numerous fields such as construction, mining, ports, and water conservancy due to its stable performance and wide applicability.

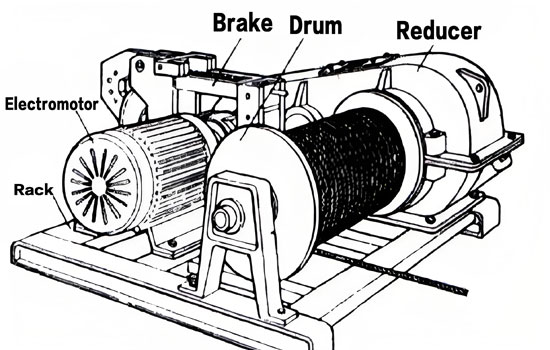

Components of the Electric Winch

Electromotor

As the power source of the electric winch, an AC motor is usually used, and its power is determined according to the load requirements of the winch.

Reducer

It is used to reduce the speed of the motor and increase the torque, ensuring that the electric winch can smoothly lift or lower heavy objects. Common types of reducers include gear reducers and worm gear reducers.

Drum

The drum is the core component of the electric winch, which is a cage-like structure used to wind steel wire ropes, thereby lifting or lowering heavy objects. The diameter and length of the drum are designed according to the specifications of the steel wire rope and the purpose of the electric winch.

Brake

The brake is used to fix the drum and prevent the heavy object from sliding down in the case of stopping or emergency situations. Common types of brakes include electromagnetic brakes and hydraulic brakes.

Steel wire ropes

They are used to directly connect the heavy object and transfer the tension to lift or lower the heavy object. They need to have sufficient strength and durability to ensure safe and reliable operation. Therefore, the selection of steel wire ropes should consider their diameter, material, and tensile strength.

Capstan

The capstan is the device that drives the drum to rotate, transmitting power to the drum to make it rotate. The capstan is usually composed of gears, transmission shafts, and transmission mechanisms.

Control system

It includes operation buttons, limit switches, and electrical control boxes, used to control the start and stop of the electric winch, as well as the lifting and lowering speed and direction of the wire rope.

Frame

It supports and fixes the various components of the electric winch, usually made of steel welding, ensuring the stability and durability of the winch equipment.

Working Principle of Electric Winches

An electric winch is based on the principle of force balance, which refers to the equilibrium relationship between gravity and other external forces. It connects the heavy object to the drum using a steel wire rope and uses the rotation of the drum to lift or lower the heavy object. When the drum starts to rotate, the heavy object will rise or fall accordingly until it reaches a balanced state.

Types of Electric Winches

Type | Rated Load KN | Rated Speed m/min | Rope Capacity m | Rope Diameter mm |

JM | 10 - 650 | 5 - 20 | 100 - 3600 | ⌀9.3 - ⌀65 |

JK | 5 - 100 | 22 - 30 | 100 - 300 | ⌀7.7 - ⌀30 |

JKL | 20 - 100 | 29 - 36 | 150 - 250 | ⌀13 - ⌀28 |

JK-D | 7.5 - 20 | 28 - 46 | 100 - 190 | ⌀9.3 - ⌀13 |

JMM | 100 - 550 | 5 - 11 | 1000 - 4800 | ⌀30 - ⌀60 |

The electric winch can be available for customizing according to your actual inquiry. | ||||

Advantages of Electric Winches

Strong and Stable Power Output with High Hoisting Efficiency

Driven by electric motors, electric winches offer significant power advantages compared to manual winches or some pneumatic winches.

On one hand, electric motors cover a wide power range, from several kilowatts for small-scale equipment to hundreds of kilowatts for large industrial-grade models. They can be flexibly matched to different hoisting requirements, easily realizing the lifting or traction of heavy loads ranging from several tons to over a hundred tons, and meeting the load-bearing demands of various working conditions.

On the other hand, the power output of electric motors is uniform and stable, which can effectively avoid load swaying or operation interruptions caused by power fluctuations, ensuring a smooth and efficient hoisting process. In continuous operation scenarios, electric winches can maintain stable work efficiency, significantly shortening the operation cycle.They are particularly suitable for high - efficiency -demanding scenarios such as assembly line operations and port loading/unloading.

Convenient and Flexible Operation with High Control Precision

Modern electric winches are generally equipped with mature control systems, making their operation increasingly convenient. Whether it is traditional button control, handle operation, or intelligent remote control and PLC linkage control, operators can easily realize functions such as starting, stopping, and adjusting the lifting speed of the equipment.

Some high-end models also feature stepless speed regulation capabilities, allowing precise control of the load's running speed according to operational needs. This not only improves operational efficiency during no-load or light-load conditions but also reduces speed during heavy-load or positioning phases, ensuring the load accurately reaches the target position and minimizing operational errors.

Additionally, electric winches have a relatively low operating threshold—operators can take up the job after simple training, reducing labor costs and operational risks.

Comprehensive Safety Assurance System for Reliable Operation

Safety is the core requirement of hoisting operations, and electric winches attach great importance to safety design with multiple protection devices.

Common protection functions include over-hoisting protection (preventing hooks or loads from exceeding the upper limit position), overload protection (automatically shutting down when the load exceeds the rated value), brake failure protection (ensuring stable braking of the load to avoid falling in case of power failure or malfunction), and emergency stop buttons. These protection devices form a complete safety protection system, which can effectively respond to sudden situations during operations and reduce the risks of equipment damage and personnel casualties.

Meanwhile, electric winches have a mature mechanical structure and high standardization of components. After strict quality inspections, they exhibit strong operational stability and low failure rates, further enhancing operational safety.

Wide Applicable Scenarios and Strong Environmental Adaptability

Electric winches feature flexible and diverse structural designs, which can be customized and adjusted according to different operating environments and requirements, resulting in an extremely wide application range.

In construction, they can be used for the traction of tower cranes and construction elevators; in mining, they can cooperate with mine hoisting equipment to realize ore transportation; in ports and terminals, they can serve as core components of loading and unloading machinery to complete the lifting of containers and goods; in water conservancy projects, they can be used for the opening and closing of sluice gates, etc.

Additionally, electric winches have strong adaptability to working environments. Some special models can work normally in harsh conditions such as high temperature, low temperature, humidity, and dust. By adopting special treatment processes such as waterproofing, dustproofing, and corrosion resistance, the reliability and service life of the equipment in complex working conditions are ensured.

Reasonable Energy Consumption and Convenient Maintenance with Low Economic Costs

From an economic perspective, electric winches have significant advantages.

On one hand, electric motors have high energy utilization efficiency. Compared with fuel-driven equipment, electric energy conversion efficiency is higher, and energy consumption remains stable during operation without significant fluctuations due to load changes. Long-term use can effectively reduce energy costs.

On the other hand, the maintenance of electric winches is relatively simple and convenient. Their core component, the electric motor, has a mature structure, and daily maintenance mainly includes basic work such as lubrication, cleaning, and component inspection, with long maintenance cycles and low maintenance costs.

Meanwhile, with the continuous development of motor technology and control technology, the energy consumption level of electric winches is constantly optimized. Some high-efficiency and energy-saving models can further reduce operational costs, improving economic benefits for enterprises.

Great Potential for Intelligent Upgrading, in Line with Industry Development Trends

Under the general trend of industrial intelligence, electric winches have excellent upgrading potential.

By integrating technologies such as the Internet of Things (IoT), big data, and artificial intelligence, functions such as remote monitoring, fault early warning, and intelligent scheduling of equipment can be realized.

For example, operators can real-time grasp data such as the equipment's operating status and load conditions through a remote platform; the system can predict potential fault risks in advance based on equipment operating parameters and issue early warning information to facilitate timely maintenance; during the collaborative operation of multiple devices, an intelligent scheduling system can achieve efficient coordination, improving overall operational efficiency.

This intelligent upgrading can not only further enhance the practicality and safety of electric winches but also promote the development of hoisting operations towards automation and intelligence, in line with the needs of modern industrial development.

Summary

Relying on the advantages such as strong power, convenient operation, safety and reliability, wide applicability, and economic energy-saving, electric winches have become indispensable core equipment in the field of lifting operations. As a crane manufacturer with more than 35 years production experience, Henan Dejun Industrial Co., Ltd. can provide the suitable lifting solutions according to the specific working condition in different industries.

- The last one:Advantages of Stage Hoist

- The next one:Overhead Crane Components

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067