Industrial Bridge Crane Introduction

Introduction

An industrial bridge crane is a common industrial lifting equipment used to lift heavy objects, also known as industrial eot crane, industrial overhead crane. It is usually composed of crane trolley, winch trolley, lifting mechanisms and other parts, and can efficiently complete the transportation, loading and unloading, and installation of heavy objects within a rectangular area. The development of industrial bridge cranes in the industry has promoted the continuous expansion and deepening of their application fields. Besides being used in traditional industrial plants, they are also widely applied in ports, manufacturing industries (such as steel mills, shipyards, automobile manufacturing, mechanical processing and other industrial workshops), large-scale warehousing and logistics, power station construction, and maintenance of large public facilities.

Types of industrial bridge cranes

According to the structure of the industrial bridge crane, it usually is divided into single girder bridge crane and double girder bridge crane.

Single girder bridge crane is an industrial crane with one main beam, end beams and electric hoists to lift light duty objects.

Industrial single girder bridge crane specification

Lifting capacity | 1 - 20 ton |

Lifting height | 6 - 30 m |

Span | 3 - 31.5 m |

Working duty | -20℃ to 60℃ |

Ambient temperature | A3 to A5 |

Track type | P24 P38 P43 |

Available to be customized according to your needs | |

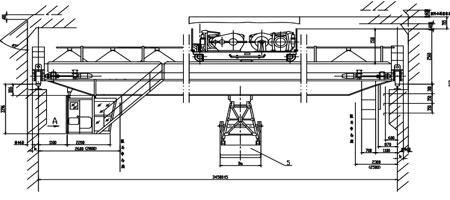

Double girder bridge crane is an industrial crane with two main beams, end beams and winch trolley to lift heavy duty objects.

Industrial double girder bridge crane specification

Lifting capacity | 20 - 800 ton |

Lifting height | 6 - 32 m |

Span | 10.5 - 34.5 m |

Working duty | -20℃ to 60℃ |

Ambient temperature | A3 to A7 |

Track type | P24 P38 943 QU100 QU120 QU70 QU80 |

Available to be customized according to your needs | |

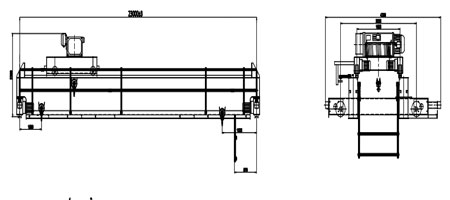

In addition, KBK bridge crane is also one type of industrial bridge crane, which is flexibly designed and installed above the workshop like a “rail transit system”, and is used for transporting relatively light objects.

KBK bridge crane specification

Lifting capacity | 125 - 2000 kg |

Lifting height | 2.5 - 12 m |

Span | 3 - 12 m |

Working class | A3 |

Ambient temperature | -20℃ to 40℃ |

Drawings of some industrial bridge cranes

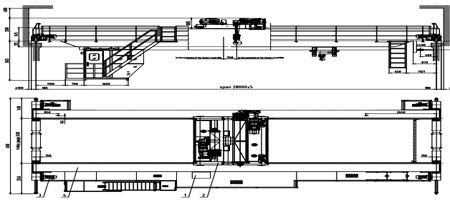

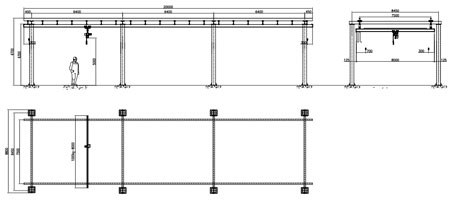

Industrial single girder bridge crane drawings

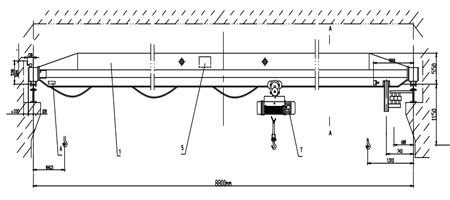

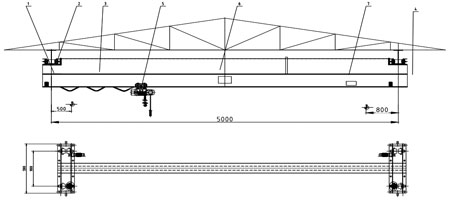

LD type industrial bridge crane drawing

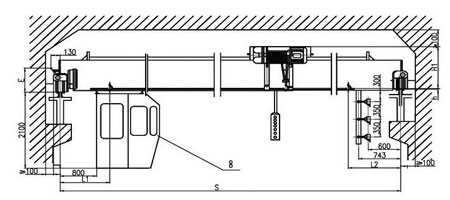

LDP type industrial bridge crane drawing

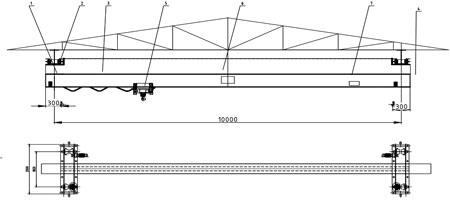

HD type industrial bridge crane drawing

LB type industrial explosion-proof bridge crane drawing

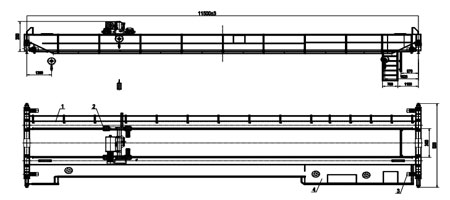

LX type indusrial bridge crane drawing

LXO type industrial bridge crane drawing

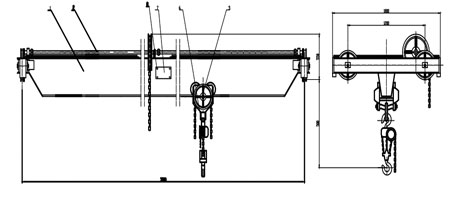

SL type industrial bridge crane drawing

SLX type industrial hand single girder suspension crane drawing

Industrial double girder bridge crane drawings

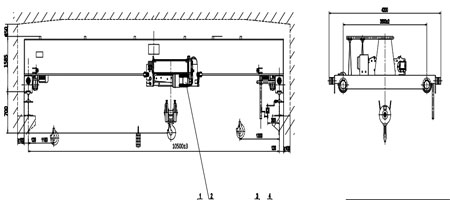

QD type industrial bridge crane drawing

QDX type industrial bridge crane drawing

QZ type industrial bridge crane drawing

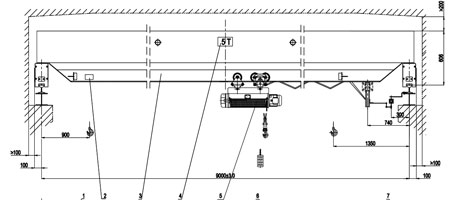

LH type industrial bridge crane drawing

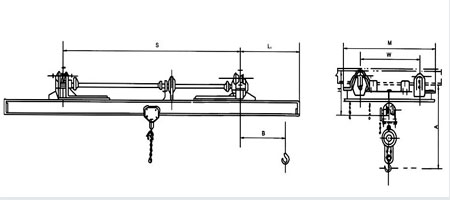

Industrial bridge crane - kbk crane drawing

kbk crane system drawing

Precautions for operating industrial bridge cranes

Due to the characteristics of large weight, large volume and high operation difficulty, safe operation of industrial bridge cranes has always been a problem of great concern to users. Djcranes (Henan Dejun Industrial Co, Ltd.) has nine points of safe operation for your reference.

1. The industrial bridge crane driver must have the corresponding driving license and experience, and be able to master the operation skills of the bridge crane.

2. Before operating the industrial bridge crane, it must be checked. The inspection contents include: whether the railway, infrastructure and surrounding environment meet the lifting operation conditions, whether the monitoring system and safety protection equipment are normal, and whether the hook, cable and other components are intact.

3. For the industrial electric bridge crane, first check whether there is an overcurrent protection device such as power supply and control loop. Secondly, check whether each control appliance is operating normally, whether the remote control is charged, and perform maintenance in accordance with electrical safety standards.

4. During the operation, communication should be kept smooth and effective oral or written communication should be carried out. Try to avoid arbitrarily changing the wiring of the original controller of the equipment, otherwise it will cause signal interference of other communication equipment.

5. The operation preparation before lifting must be checked by the industrial bridge crane driver or person in charge before it can be carried out. The inspection contents include: whether the quality of the lifting meets the rated load of the crane, whether there are obstacles in the surrounding environment of the lifting, and whether there is friction and tension between the bridge crane and the lifting object.

6. During the operation, strictly follow the operation rules. It is forbidden to use the start, stop and reverse buttons excessively, and it is not allowed to operate the overhead bridge crane in front of or after the machine

7. In the lifting process, the bridge crane driver should be careful to operate, such as strong winds, earthquakes, lightning strikes and other natural disasters, must immediately stop the operation to ensure their own safety and the safety of the surrounding personnel.

8. When the operation is stopped, the industrial crane equipment should be returned to the position to ensure that all safety measures have been implemented to avoid affecting the surrounding staff or equipment

9. Operators should be regularly trained and evaluated for safety expertise. It is best to organize a security knowledge drill regularly to improve the ability to respond quickly to situations.

In short, the safe operation procedures of the overhead bridge crane are very important, not only to protect the operator, but also to ensure the safety of the entire workplace, so that the work is more secure and comfortable. Only by strengthening safe operation and complying with safety procedures can accidents caused by bridge crane use be avoided.

Summary

Industrial bridge cranes, with their advantages of stable structure, large working space, strong adaptability and high reliability, have become indispensable basic lifting equipment in modern industrial enterprises and a key link in enhancing the level of production logistics automation and operational safety.

- The last one:Double Girder Gantry Crane Introduction

- The next one:Advantages of Stage Hoist

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067