lifting pulley-technical requirements and operating conditions of lifting pulley

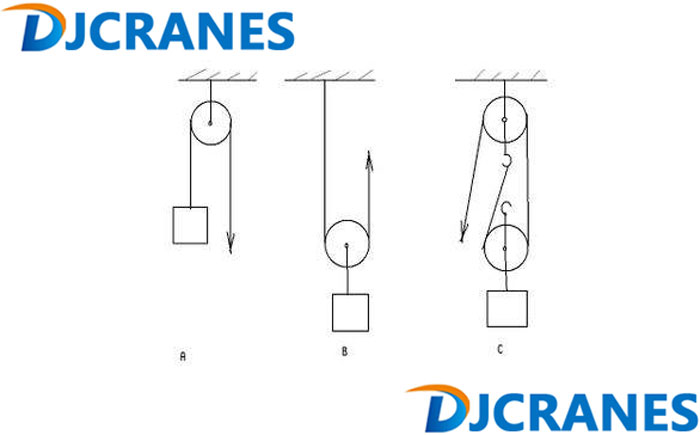

Lifting pulley also is known as iron pulley, pulley. It works with rigging, hoists, winches. It is one of the indispensable lifting tools to carry on the transportation and hoisting work to all kinds of structural equipment and components.The pulley is divided into fixed pulley, moving pulley, guide wheel and pulley group according to the nature of use, and its use is shown in the following figure.

pulley

(1) Fixed Pulley. The fixed pulley is used to support the movement of the flexible parts. When the rope is stressed, the rotor rotates while the position of the shaft remains unchanged. When in use, only the direction of the wire rope can be changed without saving power.

(2) Moving Pulley. The moving pulley is mounted on the moving shaft, and it moves up or down together with the work being pulled. Working with moving pulley saves effort, but can not change the direction of force.

(3) Guide Pulley. The guide pulley, also known as the open door slider, is similar to the fixed pulley and can only change the direction of the rope without saving effort.

(4) Pulley Group. The pulley group is a kind of lifting tool which consists of a certain number of fixed pulley, moving pulley and rigging. It can both reduce traction and change the direction of the pulling force. In the hoisting engineering, the pulley block sets are often used in order to lift mechanical equipment with larger weight with less traction. For example,when a hoist of 0.5~20 t is used to pull the end of the exit rope of the pulley group (generally called running line), the lifting task of equipment or components weighing several tons to several hundred tons can be completed.

Technical requirements of lifting tackle:

(1) The pulley shall choose its tonnage and number of wheels according to force analysis, traction force and rope capacity, and shall not be overloaded.

(2) The pulley must have a certificate of conformity, be inspected and lubricated with oil before use, and its rotating parts must be flexible.

(3) The surface of the pulley groove of the pulley shall be smooth, and there shall be no defects such as cracks and scars.

(4) It is strictly forbidden to repair hooks, rings and beams by means of welding reinforcement.

(5) When a multi-wheeled pulley uses only part of the pulley, the lifting capacity of the pulley shall be reduced accordingly, and the reduced value shall be determined in proportion to the number of pulleys. Use should be symmetrical close to use, so as not to bias load.

(6) The minimum net distance between the two pulleys of the pulley block is generally not less than five times the wheel diameter.

(7) Two (or more) groups of pulleys shall be provided with a balancing device to achieve force balance when performing a force.

(8) When decoupling is possible, measures shall be taken to seal the hooks of the pulley.

(9) The guide pulley must be selected according to the running rope pull force and the guide angle, and must not be arbitrarily tied to the use of overload.

(10) The pulley should be checked frequently, and its important parts (such as shafts, hooks, rings, and beams) should be inspected for nondestructive testing. When one of the following conditions occurs, its parts must be replaced:

① Cracks and plastic deformation are found on the hanging parts on the pulley;

②The wear depth of the pulley groove exceeds 20% of the diameter of the wire rope;

③ There is broken damage on the rim part;

④Wheel wear exceeds 2% of shaft diameter;

⑤ The wear of the pulley sleeve exceeds 10% of the wall thickness;

⑥Dangerous section wear of hooks, rings and beams exceeds 10%.

lifting pulley

Conditions of use of lifting tackle:

(1) Make sure to do a good inspection before using the pulley, if it is a newly overhauled pulley or a new pulley that has not yet been used, to carry out for rated load.

(2) Make clear the rated lifting weight of the pulley before use, and also determine the weight of the goods, must not overload, if the lifting weight can not be identified, can be measured through other tools, must not overload work.

(3) Before using the lifting pulley, check that all parts and components are in good condition before using it.

(4) The selection of the wire rope must conform to the prescribed requirements, the deflection angle between the wire rope and the pulley slot should not be too large, and the wire rope should be assembled in accordance with the prescribed requirements, so as to ensure safety during the lifting of the goods.

(5) If it is in high altitude operation or when the direction of force changes greatly, it is not appropriate to choose the hook type pulley, if it is the hook type, must seal the mouth. This can prevent the operation of excessive force and the emergence of pulley decoupling phenomenon.

(6) During the period of use, the pulley and shaft should be lubricated regularly to reduce the wear of the bearings, which can effectively prolong the service life of the pulley.

(7) When the lifting pulley is disassembled, it is forbidden to throw it, which can not only prevent it from hitting the staff, but also protect it.

Only in the work strictly according to the requirements to operate, can provide protection for work safety and the integrity of the lifting pulley. Any lifting machinery demand, please do not hesitate to Contact Us directly.

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067