LH Series Double Girder Overhead Crane with Hoist Trolley

LH Double Girder Overhead Crane with Hoist Trolley

| Lifting Capacity: | 5t to 32t |

| Span: | 10.5m to 31.5m |

| Lifting Height: | 6m to 18m |

| Working Class: | A3~A4 |

| Ambient Temperature: | -20℃ to 40℃ |

Double Girder Overhead Crane with Hoist Trolley Introduction

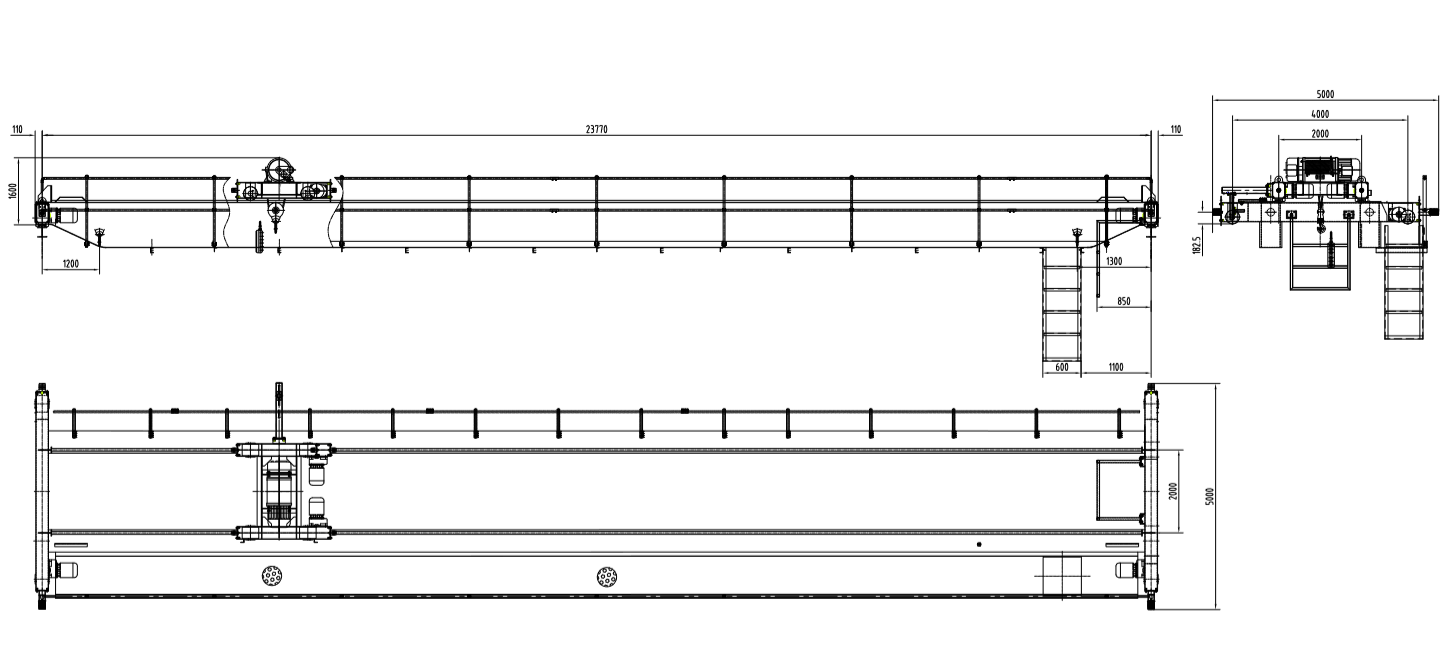

LH series double girder overhead crane with hoist trolley consists of box type main girder,end carriages, lifting trolley, long crane traveling system and electrical system. It relies on the longitudinal movement of the bridge frame along the track of the workshop, the lateral movement of the trolley along the direction of the main beam and the lifting motion of the hook.

Technical data of Electric Hoist Overhead Crane

| Technical Parameter of LH Model electric hoist overhead crane | ||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 |

| Span | m | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 0.8/8 | 0.7/7 | 0.35/3.5 | 0.6/4 | 0.6/4 |

| Trolley speed | m/min | 20 | 20 | 20 | 20 | 20 |

| Crane speed | m/min | 20/43 | 20/43 | 20/43 | 20/43 | 20/43 |

| Work duty | A4 | A4 | A4 | A4 | A4 | |

| Track type | P24 | P24 P38 | P38 | P38 | P43 | |

Application of Double Girder Overhead Crane with Hoist Trolley

LH series trolley double girder overhead cranes are industrial-strength lifting devices that are widely used in various operations. For example: manufacturing warehouses, assembly workshops, steel plants, metallurgical casting workshops, power plants and other workshop operations.

■ Metalworking and steel mills - Bridge cranes are crucial in transporting metal, raw materials, finished products, and machinery, and equipment in metalworking and steel mills.

■ Power generation and transmission - double girder bridge cranes are valuable in handling heavy equipment, transformers, and other components in power generation and transmission operations.

■ Manufacturing and assembly - LH series double girder bridge cranes with hoist trolley are essential in transporting heavy machinery and equipment, raw materials, and finished products in manufacturing and assembly operations.

■ Mining and quarrying - double girder overhead cranes are crucial in transporting heavy machinery, equipment, and materials in mining and quarrying operations.

■ Construction and infrastructure projects - LH series double girder bridge cranes are invalid in transporting heavy building materials and pre-fabricated building components in construction and infrastructure projects.

Advantages of Double Girder Overhead Crane with Hoist Trolley

■ Compact structure and high performance.

■ Soft starting and stopping.

■ Safe and stable traveling, long life.

■ Low noise, commodious cabin with good view.

■ High quality automatic welding and NDT inspection.

■ Crane drive: IP54 or IP55, level F insulation.

Features of Double Girder Overhead Crane with Hoist Trolley

■ Main girder is made by CNC cutting for complete steel plate, with high surface flatness and accuracy, National standard 24# 38# 43# adapted for cross travel rail.

■ End carriages are welded with rectangular tubes, buffers equipped for safety crane travel

■ Main girder and End carriages assembled with bolts and nuts easily and fast.

■ Hoist trolley consists of hoist, trolley frame, hook, pulley etc. Hoist is fixed on trolley frame by bolts and nuts, working stable and smoothly.

■ Electrics used Schneider brand original from France.

■ Motor, reducer, brake best brand in China

■ Working class A3, A4

■ Control can be pendant control, wireless remote control and cabin control.

■ Safety devices included, such as buffer, limit switch, overload limiter, voltage and current protection equipment etc.

FAQ on Double Girder Overhead Crane with Hoist Trolley

1. How many tons can this bridge crane lift?

The lifting capacity of a crane depends on its specific model and configuration, and our lifting equipment can handle loads of hundreds of tons.

2. Can this crane be customized to meet specific needs?

It can be customized according to the specific requirements put forward by customers. This may involve some very specific parameters: rated capacity, lift height, span, voltage, etc.

Our company considers that the working environment of each crane is different, so each lifting equipment is specially customized.

① Customized cranes can better adapt to different working environments.

For example, in the petroleum industry, lifting equipment needs to be able to withstand high temperature and corrosive environments, and customized equipment can use special materials and coatings to enhance corrosion resistance.

② Provide higher efficiency and lower energy consumption during actual use.

③ Can provide higher security.

According to the safety requirements of different industries, when designing a crane, various safety devices and protection measures will be added to reduce the risk of accidents and protect the safety of workers.

3. What safety measures should be taken when using the LH bridge crane?

When operating an LH overhead traveling crane, it is essential to ensure that all safety devices are installed and functioning properly.

Safety devices include lifting limit switch, weight limit switch, rotation limit to prevent the lifting stroke from exceeding the limit; lifting weight limiter or electronic scale to prevent overloading of heavy objects; stroke limit switch, single limit, double limit Limit, with pre-deceleration limit, to prevent large and small cars from running beyond the stroke; anti-collision device, laser detection anti-collision, distance detection through laser reflection; buffer, absorbing collision kinetic energy; electrical interlock switch, door switch, boarding request switch; overspeed switch, detects the speed of the lifting motor, and works when the motor stalls; safety brake, the safety brake directly locks the reel, etc.

If you have other special requirements for safety devices, please let us know clearly.

4. How long is the service life of the LH bridge crane?

When the crane is used and worn for a long time, its lifespan will be reduced, and each component will gradually become more and more seriously aged and damaged, and the crane as a whole will become "scarred".

Its service life will also vary depending on various factors such as use, maintenance and environmental conditions. Cranes that exceed the service life have entered the scrapping stage. Every region has strict regulations on crane scrapping. When the scrapping time is reached, scrapping and scrapping must be carried out. Those who do not perform scrapping will be punished.

If you want to know the service life of each bridge crane accurately, please contact us.

5. What is the delivery time for the order?

Order lead times may vary by model and specification.

Generally, the production cycle of bridge cranes is about 10-15 days. If it is a large-tonnage crane, such as a crane with a capacity of more than 32 tons, the production cycle will be slightly longer, about 30-50 days. It is recommended to consult us for an accurate estimate.

Double Girder Overhead Crane with Hoist Trolley Case

Double Girder Overhead Crane with Hoist Trolley

- The last one:No information!

- The next one::QD Series Double Girder Overhead Crane with Winch Trolley

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067