Crane Tongs: Different Types Lifting Tongs for Industrial Loads

Crane Tong

Crane tongs includes log tongs, skidding tongs, timber tongs, log lifting tongs, industrial tongs, metal tongs, rail tongs, ingot tongs, scissor lifting tongs, billet tongs etc. Dejun Industrial can provide you customized crane tongs according to your lifting materials.

Crane tongs includes log tongs, skidding tongs, timber tongs, log lifting tongs, industrial tongs, metal tongs, rail tongs, ingot tongs, scissor lifting tongs, billet tongs etc. Dejun Industrial can provide you customized crane tongs according to your lifting materials.

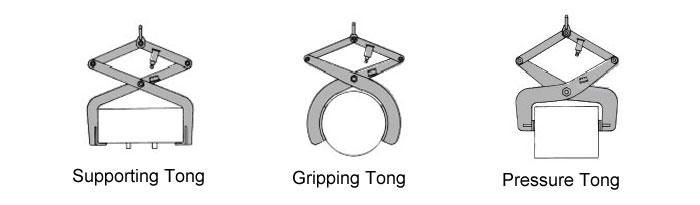

Three basic tong configurations and application concepts

Supporting Tongs

Supporting tongs are for single-size objects that have support clearance underneath, such as boxes, crates, bins and containers. The lifting feet of the tong support the load and maintain it on a horizontal lifting plane.

Gripping Tongs

Gripping tongs are for materials such as ingots, rolls, tubes, pipes and other round or cylindrical objects. The tong extends beyond and below the center of the load to provide additional support. The diameter of the load may vary by approximately 25%, but the variation in length is generally unlimited.

Pressure Tongs

Pressure tongs grip the vertical sides of slabs, bales, boxes, billets and other flat or round objects. Pads on pressure tongs provide surface friction or penetration of the load to maintain a safe hold during handling. Pads can be provided with rubber, belting, pins, hardened points, serrated bits and other materials.

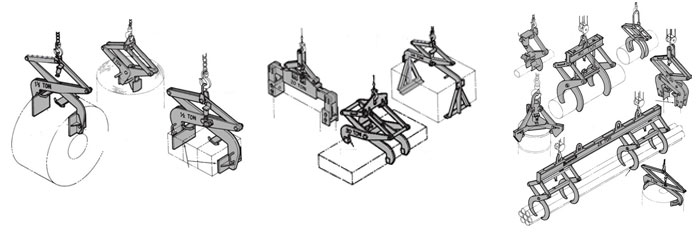

Crane Lifting Tongs Application Types

Lifting Tongs Application Types

Horizontal Coil Tongs

Horizontal coil tongs is suitable for lifting horizontal steel coils of hot rolled, cold rolled and different specifications. The lifting capacity is 8 tons to 50 tons.

The clamp arm opens and closes in the form of electric screw drive, electric rack drive and electric lever drive. There are electric rotary horizontal clamps, the jaws can be made mechanically and electrically turned over 90°, and can be equipped with an electrical detection device or a polyurethane protection device.

Horizontal Coil Tongs

Vertical Coil Tongs

Vertical coil tongs is suitable for loading and unloading vertical steel coils in the cover furnace area and other occasions, with a lifting capacity of 8 tons to 50 tons. The mechanical lever type is single-sided grip type or double-sided grip type. The clamping method, the steel coil gravity generates the clamping force through the lever mechanism, and the auxiliary hook is used to drive the auxiliary hook opening and closing clamp, and the vertical coil tongs structure is reasonable, safe and reliable.

Vertical Coil Tongs

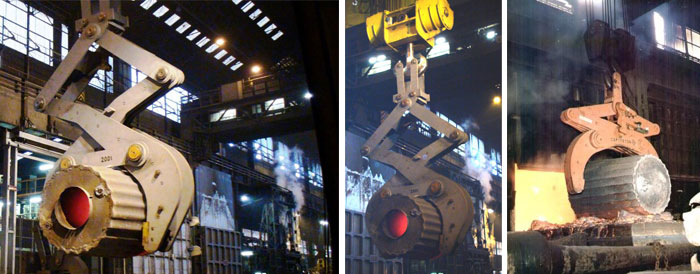

Block Tongs

The Automatic Block Tong is designed to lift single ingots and blocks. Tong levers can also be designed, to grip ingots vertically and deposit them horizontally, or vice versa. The tongs are robustly engineered for heavy duty application to meet the severe demands of steel mills.

The crane operator controls the entire lifting process from the crane cabin, by positioning the tong above the center of the ingot. The suspension assembly is designed to accommodate standard crane hooks. The standard suspension is fixed by pull pins. Customized suspensions on request.

Automatic Block Tongs

Slab Tongs

Crane slab tongs include automatic slab tongs,hoist slab tongs, dragline slab tongs, motorized slab tong and hydraulic slab tongs. The Automatic Slab Tong is designed to lift either one or several slabs simultaneously, in a horizontal position.

The tongs are robustly engineered for heavy duty application to meet the severe demands of steel mills. The crane operator controls the entire lifting process from the crane cabin by placing the tong above the center of the slab. The suspension assembly is designed to accommodate standard crane hooks. The suspension is fixed by pull pins. Customized suspensions produced on request.

Automatic Slab Tongs

Billet Tongs

The Hydraulic operated Billet Tong is designed to lift either one or several billets simultaneously. The tongs are robustly engineered for heavy duty application to meet the severe demands of steel mills. The lifting legs can be hydraulically activated. The crane operator controls the entire lifting process from the crane cabin.

The tong is operated by an electric driven hydraulic system, mounted on the tong. The preposition of the scissors is hydraulically actuated. The electrical circuit to the control box is carried out by plug-in connection. This enables quick removal of the tong from the crane. The suspension assembly is designed to accommodate standard crane hooks. The standard suspension is fixed by pull pins.Customized suspensions produced on request.

Hydraulic Billet Tongs

The Automatic Billet Tong is designed to lift either one or several billets simultaneously, in a horizontal position. The tongs are robustly engineered for heavy duty application to meet the severe demands of steel mills.

The crane operator controls the entire lifting process from the crane cabin by placing the tong above the center of the billets before the lifting stroke starts. The suspension assembly is designed to accommodate standard crane hooks. The standard suspension is fixed by pull pins. Customized suspensions on request.

Automatic Billet Tongs

Hydraulic Aluminium Block Tongs

The Hydraulic operated Aluminum Block Tong is designed for the vertical removal of aluminum ingots from their casting moulds and the stacking of the same in the horizontal position. The tongs are robustly engineered for heavy duty application to meet the severe demands of aluminum rolling mills.

The crane operator controls the entire lifting process from the crane cabin. The tong is operated by an electric driven hydraulic system, mounted on the tong. The lifting scissors are pre-positioned hydraulically. The electrical circuit to the control box is carried out by plug-in connection. This enables quick removal of the tong from the crane. The suspension assembly is designed to accommodate standard crane hooks. The standard suspension is fixed by pull pins. Customized suspensions on request.

Hydraulic Aluminium Block Tongs

Cylinder Roll Tong

The Automatic Cylinder Roll Tong is designed to lift single or double rolls, by gripping the rolls with its two automatic pairs of lifting arms. The tongs are robustly engineered for heavy duty application to meet the severe demands of a rolling mill.

The crane operator controls the entire lifting process from the crane cabin. The suspension assembly is designed to accommodate standard crane hooks. The suspension is fixed by pull pins. Customized suspensions on request.

Cylinder Roll Tong

The Motorized Cylinder Roll Tong is designed to lift single or double rolls by the cylinder. The Cylinder Roll Tong R&P is designed to lift single, or double backup rolls. Its two independently powered pair of lifting arms grip either chock or at the shaft end.

Mechnical Cylinder Roll Tong

Sheet Lifter Multipurpose Tongs

The three various Motorized Sheet Lifter - Rack & Pinion (R&P), Fixed and Telescopic Type- are multipurpose tongs to lift single- or multiple bundles, sheets, plates and other material in various dimensions, stacked horizontally. Each sheet-metal-tong is tailored and manufactured to specific customer requirements.

The crane operator controls the entire lifting process from the crane cabin by placing the tong above the sheet pack until the lifting shoes can grip under the pack. Drive is provided by a three-phase gear motor and R&P transmission.

The electric circuit is wired by plug-in into a terminal box on the tong unit. The suspension assembly is designed to accommodate standard crane hooks and is fixed by pull pins. Customized suspensions on request.

Sheet Lifter Multipurpose Tongs

info@dejunindustry.com

info@dejunindustry.com +86 13721448067

+86 13721448067